Resistors ... How much important is contained in this word for those who are fond of electronics or are constantly working with it. However, for complete immersion in the world of electronics, it is necessary to know at least superficially and be able to determine the marking of chip resistors.

The abbreviation "SMD" stands for Surface Mounted Devices, which in translation into Russian means " surface mount device". And this is true - resistors are installed above the surface on special mounts. These devices are mounted on printed circuit boards.

One of the significant advantages of smd chips is their small size. On a single PCB you can easily place dozens (if not hundreds) of similar products. Also, due to high quality and low cost, resistors have gained extraordinary popularity in the electronics market.

Thanks to constant progress, new models of resistor chips are appearing, the marking and characteristics of which are constantly changing. In total, there are 3 types of products on this market:

- Made in the Soviet period (now significantly losing popularity).

- Modern models.

- SMD Resistors.

In this article, we dwell on the labeling of the latter type, because it is most interesting.

Labeling principles

All SMD chips are labeled differently. The fact is that each product has its own size and tolerance value. Accordingly, so as not to cause confusion, the manufacturers decided to highlight 3 main groups for marking:

- Products marked with 3 digits.

- Models marked with 4 digits.

- Devices with 2 digits and one letter.

Each of these types is worth considering in more detail.

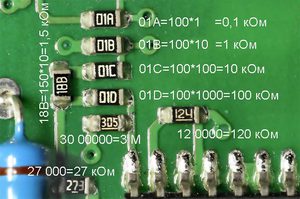

The first group includes products (numbers 103, 513, etc.) with a tolerance of 2%, 5% or 10%. Under the first two digits of the mantissa, and the last one indicates the exponent 10. The last value is necessary for calculating the resistor value (measured in Ohms). Also, in some models there is a letter "R", which indicates the decimal point.

The second group, it was decided to include models with a size of 0805 and above, as well as having a tolerance of 1%. The principle is similar to the first group of resistors: the first 3 digits indicate the mantissa, and the fourth - the degree value, which has a base of 10. In addition, here, as in the previous type, the last number means the nominal value of the model (in Ohms), and the letter R stands for decimal point. It is worth mentioning that devices with frame size 0402 are not marked.

The second group, it was decided to include models with a size of 0805 and above, as well as having a tolerance of 1%. The principle is similar to the first group of resistors: the first 3 digits indicate the mantissa, and the fourth - the degree value, which has a base of 10. In addition, here, as in the previous type, the last number means the nominal value of the model (in Ohms), and the letter R stands for decimal point. It is worth mentioning that devices with frame size 0402 are not marked.

Finally, in the last group are smd chips with a size of 0603 and a tolerance level of 1%. The numbers indicate the code in the EIA-96 table (see below), and the letter indicates the value of the multiplier:

- A is the number 10 in the zero degree

- B - base 10 with degree 1

- C is the number 10 to the power of 2

- D \u003d 10 3

- E \u003d 10 4

- F \u003d 10 5

- R \u003d 10 -1

- S \u003d 10 -2

Labeling Explanation

To install or work with an SMD resistor, you need to know and be able to decrypt numbers and letters. This process can be divided into 2 types.

Normal decryption

As mentioned above, in the manufacture smd resistors, indestructible labeling rules apply. They are designed to the buyer was able to easily identify the mantissa and the value of resistance. Therefore, all that is required is a piece of paper with a pen or a mathematical mindset.

Start with simple example - determination of resistance for products with a tolerance of 2%, 5% or 10% (these are those models that have 3 digits in the marking). Suppose the resistor shows the number 233. This means that you need 23 times 10 in the third degree. As a result, it turns out that the product has a resistance of 23 KOhm (23 x 10 3 \u003d 23,000 Ohm \u003d 23 KOhm).

A similar situation is with models that have 4 digits in the description. Suppose the number 5401 is indicated on the product. Performing similar calculations, we obtain a resistance of 5.4 KOhm (540 x 10 1 \u003d 5,400 Ohm \u003d 5,4 KOhm).

Things are completely different with the decoding of the designation of products on which numbers and letters are indicated. As described above, this will require eIA-96 table (it can be easily found on the Internet). Substituting the numbers in the corresponding line and translating the letter into a numerical expression, you can easily calculate the resistance. For example, 04D means that the resistance is 10.7 KΩ (107 x 10 3 \u003d 107 000 Ω \u003d 10.7 KΩ).

Decryption through services

Progress does not stand still. Are constantly being introduced modern technologies, new approaches are being developed, in other words, a person’s life is becoming more and more comfortable. In today's world, even for resistance calculations for SMD chips, there are good services and programs.

Progress does not stand still. Are constantly being introduced modern technologies, new approaches are being developed, in other words, a person’s life is becoming more and more comfortable. In today's world, even for resistance calculations for SMD chips, there are good services and programs.

On the Internet, you can easily find many sites that provide the opportunity to calculate resistance. In most cases, this service is a calculator for calculating the resistance of a resistor. Here are just a few of them.

Modern radio equipment is built mainly on the so-called chip components, these are chip resistors, capacitors, microcircuits, etc. The output radio components that we used to solder from old televisions and tape recorders and which radio amateurs usually use to assemble their circuits and devices are becoming less common in modern radio equipment.

What are the advantages of using such chip elements? Let's figure it out.

Pros of this type of installation

Firstly, the use of chip components significantly reduces the size of finished printed circuit boards, their weight decreases, as a result, a small compact case will be required for this device. So you can assemble very compact and miniature devices. The use of chip elements makes it possible to save a printed circuit board (fiberglass), as well as ferric chloride for etching, in addition, you do not have to spend time drilling holes, in any case, it does not take so much time and money.

The boards made in this way are easier to repair and easier to replace the radio elements on the board. You can make double-sided boards, and place elements on both sides of the board. Well, cost savings, because the chip components are cheap, and it’s very profitable to take them in bulk.

To begin with, let's define the term surface mount, what does this mean? Surface mounting is a technology for the production of printed circuit boards, when the radio components are placed on the side of the printed tracks, to place them on the circuit board you do not have to drill holes, in short, this means "surface mounting". This technology is the most common today.

In addition to the pros, there are certainly disadvantages. The boards assembled on the chip components are afraid of bends and bumps, because after that, radio components, especially resistors with capacitors, simply crack. Chip components do not tolerate overheating when soldering. From overheating, they often crack and microcracks appear. The defect does not manifest itself immediately, but only during operation

Types and types of chip radio components

Resistors and Capacitors

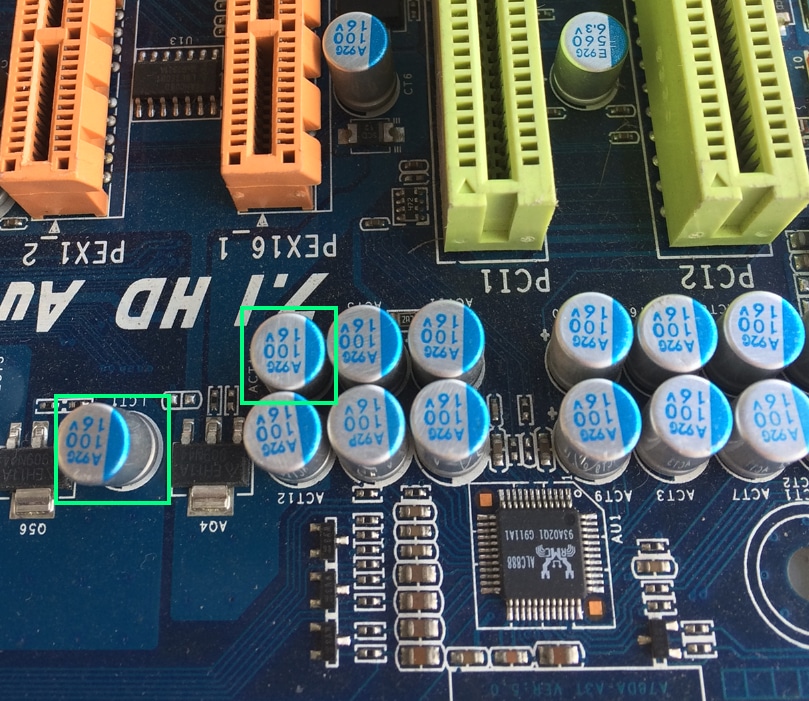

Chip components (resistors and capacitors) are primarily divided by size, there are 0402 - these are the smallest radio components, very small ones, such as those used in cell phones, 0603 are also tiny, but slightly larger than the previous ones, 0805 are used for example in motherboards boards, the most common, then go 1008, 1206 and so on.

Resistors:

Capacitors:

Below is a more table showing the sizes of some elements:

- 1.0 × 0.5 mm

- 1.6 × 0.8 mm

- 2.0 × 1.25 mm

- 3.2 × 1.6 mm

- 4.5 × 3.2 mm

All chip resistors are indicated coded, although a method for decrypting these codes is given, many still do not know how to decipher the values \u200b\u200bof these resistors, in connection with this I painted the codes of some resistors, take a look at the table.

Note: In the table error: 221 "Ohm" should be read as "220 Ohm".

As for the capacitors, they are not marked and marked in any way, so when you buy them, ask the seller to sign the tapes, otherwise, you will need an accurate multimeter with the function of determining capacities.

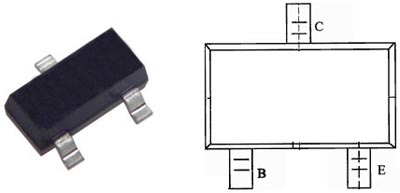

Transistors

Mostly radio amateurs use SOT-23 transistors, I will not talk about the rest. The dimensions of these transistors are as follows: 3 × 1.75 × 1.3 mm.

As you can see they are very small, they need to be soldered very carefully and quickly. Below is a pinout of the findings of such transistors:

The pinout for most transistors in such a case is just that, but there are exceptions, so before you solder the transistor, check the pinout of the terminals by downloading the datasheet to it. Such transistors in most cases are indicated with one letter and 1 digit.

Diodes and Zener Diodes

Diodes, like resistors with capacitors, come in different sizes, larger diodes are indicated by a strip on the one hand - this is the cathode, but miniature diodes can differ in marks and pinout. Such diodes are usually indicated by 1-2 letters and 1 or 2 digits.

Zener diodes, as well as diodes, are indicated by a strip with the edge of the case. By the way, because of their shape, they like to run away from the workplace, they are very smart, and if they fall, you won’t find it, so put them in the lid of a jar of rosin, for example.

Microchips and microcontrollers

Chips come in different cases, the main and often used types of cases are shown below in the photo. The worst case type is SSOP - the legs of these microcircuits are so close that it’s almost impossible to solder without snot, the nearest outputs stick together all the time. Such microcircuits need to be soldered with a soldering iron with a very thin sting, and preferably with a soldering hairdryer, if there is one, I painted the methodology for working with a hairdryer and solder paste in this one.

The next type of case is TQFP, the photo shows a case with 32 legs (ATmega32 microcontroller), as you can see the case is square, and the legs are located on each side of it, the main drawback of such cases is that it is difficult to solder them with an ordinary soldering iron, but you can. As for the other types of cases, it is much easier with them.

How and how to solder the chip components?

The radio components chip is best soldered by a temperature-controlled soldering station, but if there is none, then it remains only a soldering iron, which must be turned on through the regulator! (without a regulator, in most ordinary soldering irons, the tip temperature reaches 350-400 * C). The soldering temperature should be about 240-280 * C. For example, when working with lead-free solders having a melting point of 217-227 * C, the temperature of the soldering iron tip should be 280-300 ° C. During the brazing process, it is necessary to avoid excessively high tip temperatures and excessive brazing times. The soldering iron tip must be sharpened sharply, in the form of a cone or a flat screwdriver.

Printed tracks on the circuit board must be irradiated and coated with an alcohol-rosin flux. It is convenient to support the component chip during soldering with tweezers or a fingernail, you need to solder quickly, no more than 0.5-1.5 sec. First, solder one terminal of the component, then remove the tweezers and solder the second terminal. The microcircuits must be very precisely combined, then the extreme pins are sealed and checked once again whether all the pins exactly get on the tracks, and then the other pins are sealed.

If adjacent pins stick together when soldering microcircuits, use a toothpick, attach it between the microcircuit pins and then tap one of the pins with a soldering iron, it is recommended to use more flux. You can go the other way, remove the screen from the shielded wire and collect solder from the terminals of the microcircuit.

Some photos from the personal archive

Conclusion

Surface mounting allows you to save money and make very compact, miniature devices. For all its disadvantages that take place, the resulting effect undoubtedly indicates the prospects and relevance of this technology.

SMD components (chip components) Are components electronic circuitapplied to a printed circuit board (motherboard of a computer, laptop, tablet, smartphone, hard disk, etc.) using surface mount technology - SMT technology (English surface mount technology). That is, all electronic elements that are “fixed” to the board in this way are called SMD components (English surface mounted device).

This type of installation is characterized by the fact that, unlike the older technology of through installation (when a hole in the PCB is drilled for an electronic component: transistor, resistor, capacitor), SMD components are much more compact on the printed circuit board. The components themselves are significantly less.

If you pay attention to the modern laptop motherboard, you can see that it is SMD components that make up the bulk of the details on the board - there are a lot of them and they are very heaped (small multi-colored squares and rectangles of gray, black), and on both sides of the PCB. In the following figure, the SMD components are marked in red.

The motherboard of a tablet or smartphone is made exclusively using SMT (surface mount) technology and SMD elements, as there is no space and need for through-mounting.

In motherboards of stationary computers, both installation technologies are used more often than others. In the figure below, the through-hole elements are marked in green. The contacts of the components (electrolytic capacitors in this case) are inserted into special holes in motherboard and solder on the back.

Benefits of SMD Components and Surface Mount

- Smaller SMD components compared to elements used in through installation;

- Significantly higher board density;

- Higher density of tracks (compounds) on the PCB;

- Components can be located on both sides of the board;

- Small errors during SMT installation (soldering) are automatically corrected by surface tension of molten tin (lead);

- Better resistance to mechanical damage due to vibration;

- Lower resistance and inductance;

- There is no need to drill holes, including, as a consequence, a lower initial cost of production (economic effect);

- More adapted to automated assembly. Some automated lines can accommodate more than 136,000 components per hour;

- Many SMD components cost less through-the-box analogs;

- Suitable for devices with a very low profile (height). The circuit board can be used in a case with a thickness of only a few millimeters.

disadvantages

- Higher requirements for the production base and equipment;

- Low maintainability and higher requirements for repair specialists;

- Not suitable for mounting connectors and connectors, especially when used in the case of frequent disconnection-connections;

- Not suitable for use in high power equipment and under heavy loads.

Using materials: Surface-mount technology,

Car generator and how to check it

Car generator and how to check it Safe use of household electrical appliances

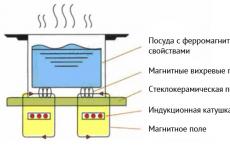

Safe use of household electrical appliances Economical Electric Cookers

Economical Electric Cookers